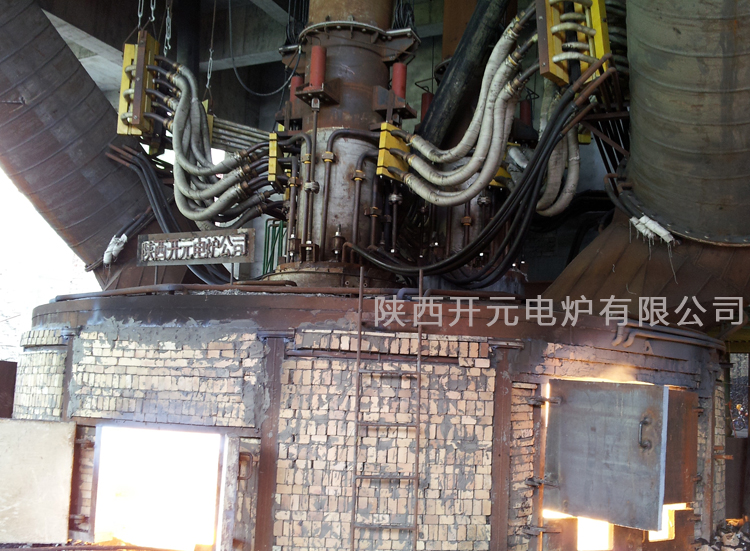

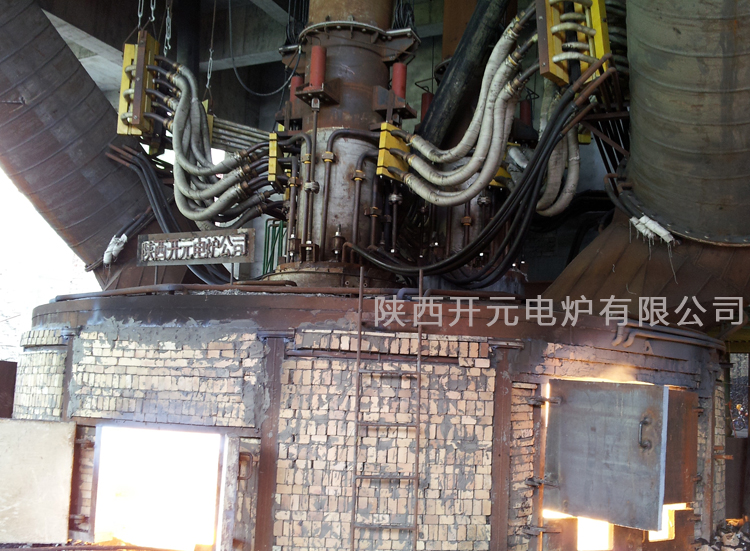

The submerged arc furnace is used for melting of silicon series, manganese

series, chrome series, nickel series ferroalloy and other ferroalloy, calcium

carbide, yellow phosphorus During work the electrodes are submerged into

material, work principle of SAF is to melt the furnace materials(granular or

powder- form) utilizing the heat of arc and resistance so to make reduction to

oxides

TECHNICAL PRIORITY

MAIN TECHNICAL PARAMETERS

Rational selection of basic parameters Power density on furnace

bottom power gradient current density of electrode voltage

gradient reactance of high current conductor system as

Well as current

density of HCCS guarantee electrodes reliably submerged into furnace material

, reach to latent melting state as well as higher productivity and lower

electric

consumption

High current conductive system

Strictly adhere the

following design criterion minimum system impedance maximum active

power maximum power factor lower asymmetrical coefficient of three phase

impedances regarding to the structure of HCCS its length have to be made as

shorted as possible, and the connecting points have to be as fewer as possible,

and, the materials with higher conductivity, lower contact resistance and

identical expansion coefficient have to be used preferably so as to reduce

power loss and hot stop of work In the space surrounding the HCCS, the

magnetic metals should be minimized and all the steel structures must be earthed

well; The high current conductors have to be supported by nonmagnetic stainless

steel parts

Electric control system

This control system has the

following functions of measuring, control, protection, operation, management and

status monitoring promote the submerged arc furnace becoming large scale,

control automation, symmetry of three phase power, make the electric power and

thermal energy to be centralized at centre of furnace and enabling the main

sinking zone is located at the center of pitch circle of electrodes and so

electric consumption reduced and output raised

Insulation

Proper multi-layer insulation and

sealing no arcing and no electric leakage occurred during operation, less

failures, higher operating ratio , normal production can be guaranteed

Matching equipment purchased

All the purchased

matching equipment are of the products with advanced top quality, which covers

furnace transformer high voltage power supply system hydraulic system as well

as the purchased metallic materials

Advanced manufacturing techniques

Professional

manufacturing techniques with advanced skills, based on many years experiences

with rationality , economy and reliability and requirements of design drawing to

manufacture

All the parts and components of furnace

Take responsibility for customer

Frequently occurred

failures on quality have been improved, for example, the electrode clamping

mechanism of DEMAG design and conductive copper jar are utilized with proper

conductive property , no water leakage and no magnetic induction The clamping

ring has been modified and no oil leakage occurred In the course of design and

manufacturing , the change of market status is considered in full

The

specification and data of furnace can fully meet the requirements of

customer Product quality on design, manufacturing, installation are to be

carried on conforming to international standards ISO9001 and therefore our

products have stronger competition priority